Beam Layout Welding Questions

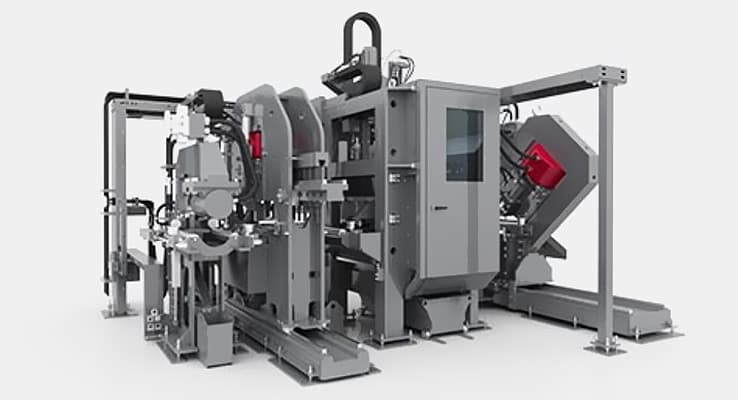

Each section can carry approximately 4,000 pounds of load. To reduce friction between the turning beam and the slower moving beam at the welder's entrance, conveyor speeds can be synchronized with the input speed of the welder.